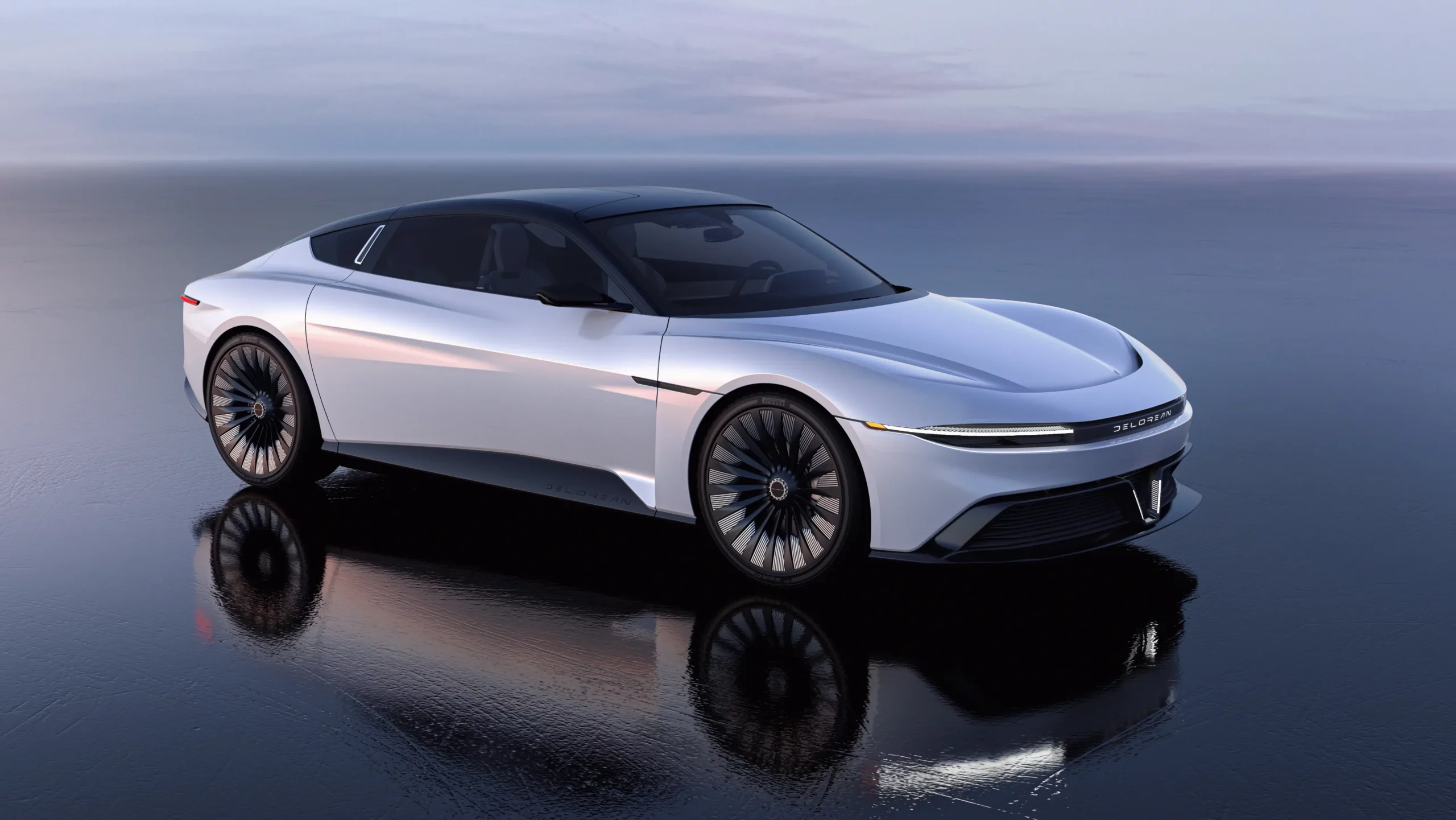

DeLorean is unapologetically human.

A New Energy mobility brand.

We have a clear vision of our future, knowing it does not represent today.

THE FUTURE WAS NEVER PROMISED

THE FUTURE WAS NEVER PROMISED

The DMC-12 was never meant to be a static interpretation of the brand, the brand would constantly evolve. Our icons are reimagined. DMC is and always was in constant evolution. An Icon is validated over time but to constantly reimagine mobility allows new icons to come into existence.

REBELLIOUS - ICONIC - DESIGN

REBELLIOUS

ICONIC

DESIGN

0-88

Estimated*

0-60

Estimated*

TOP SPEED

Estimated*

RANGE

Estimated*

BATTERY

Estimated*

DRAG COEFF.

Estimated*

RANGE

Estimated*

BATTERY

Estimated*

DRAG COEFF.

Estimated*

*Images and videos shown contain pre-production vehicles — actual production vehicle performance may differ slightly. Some range and charge times are preliminary manufacturer estimates based on the EPA test cycle and are not official EPA values. All official EPA values are noted. Vehicle range varies with conditions including weather, driving behavior, vehicle condition and load, and battery age.

TECHNICAL SPECIFICATION

Our vehicles hold minutes, it prolongs the moments of excitement and captivates all senses. Take time to stop.

“The Alpha5 is for people that love to drive.”

“Design comes from inspiration and a renowned heritage is a perfect input. This gave us a clear direction that has been projected forward thanks to the creativity of a passionate team.”